Waterproofing and corrosion resistance are primary qualities for exterior tank coatings. For outside tanks with temperature-sensitive contents, reflective or UV protective top coatings ought to be used. Epoxy coatings with polyurethane prime coats are typically exceptional selections as epoxy resin is a sturdy materials that withstands put on and tear and polyurethane protects from UV damage. Good high quality paint jobs for a tank sometimes involve sandblasting to a commercial blast spec SSPC SP6 and priming the entire floor with a coat of epoxy and a coat of high solids polyurethane. These paint jobs will typically final years, with most averaging around 18 years. You can use one of the best coating/paint merchandise on the earth, but when the floor is not ready properly before the appliance, untimely coating failure and WWW.Heart-Hotel.com substrate metal deterioration is inevitable. Depending on the particular circumstances at hand, there’s a stunning stage of variability in how the appliance course of is performed and which forms of industrial coating systems are best fitted to the job.

Industrial Facilities

The aesthetic of your tank is often as important because the corrosion safety. More and more, tank owners are wanting to construct a landmark and a reference point for the group. We’ll assist you with understanding which types of excessive efficiency coating merchandise will maintain your investment looking high notch for the long haul. An epoxy tank coating varieties a troublesome layer of film over the floor, which is of course proof against the elements and plenty of types of chemical compounds. This type of business tank coating is similar to plastic, which provides waterproofing to your coated floor.

Methods of Storage Tank's Corrosion Protection

Our dedication to safety is backed by our ISN RAVS Plus® verified HSE status. The soil corrosion could also be prevented by arranging water-proof layer and through the use of electro-chemical protection, when galvanic protectors are linked to the tank bottom. Apart from this, the bottom could additionally be effectively protected via cathodic safety. For this reason, it's necessary that crews spending protracted periods of time portray inside a tank wear air-supplied respirators. In addition to those hoods, cautious consideration must be given to air circulation. Inside Coating Systems three and www.garagesale.es 4 (ICS No. and No. 4) are thought-about to have a service life approaching thirty years. These long-lasting lining methods have been proven to reduce life cycle costs for municipalities and privately-owned water techniques.

Industrial Painting USA

Interior wet surfaces (exposed to saved water or its vapor) are generally coated with a three-coat zinc-epoxy-epoxy system with a minimum dry movie thickness, NSF Standard 61-approved for potable water. Delve into industrial / industrial cleaning, portray, coating, and flooring subjects. Electrochemical corrosion safety of the structural parts of the tank is carried out by floor and cathodic safety items. If the steel frameworks of tank roof and higher rings of the shell show extremely high tempo of corrosion course of it is attainable to use inert-gas environment as additional technique of corrosion protection. Moreover, you should provide periodic examination of the complete surface of the tank not lower than as quickly as in each 5 years for revealing corrosion injury and the areas of surface with broken pain coating.

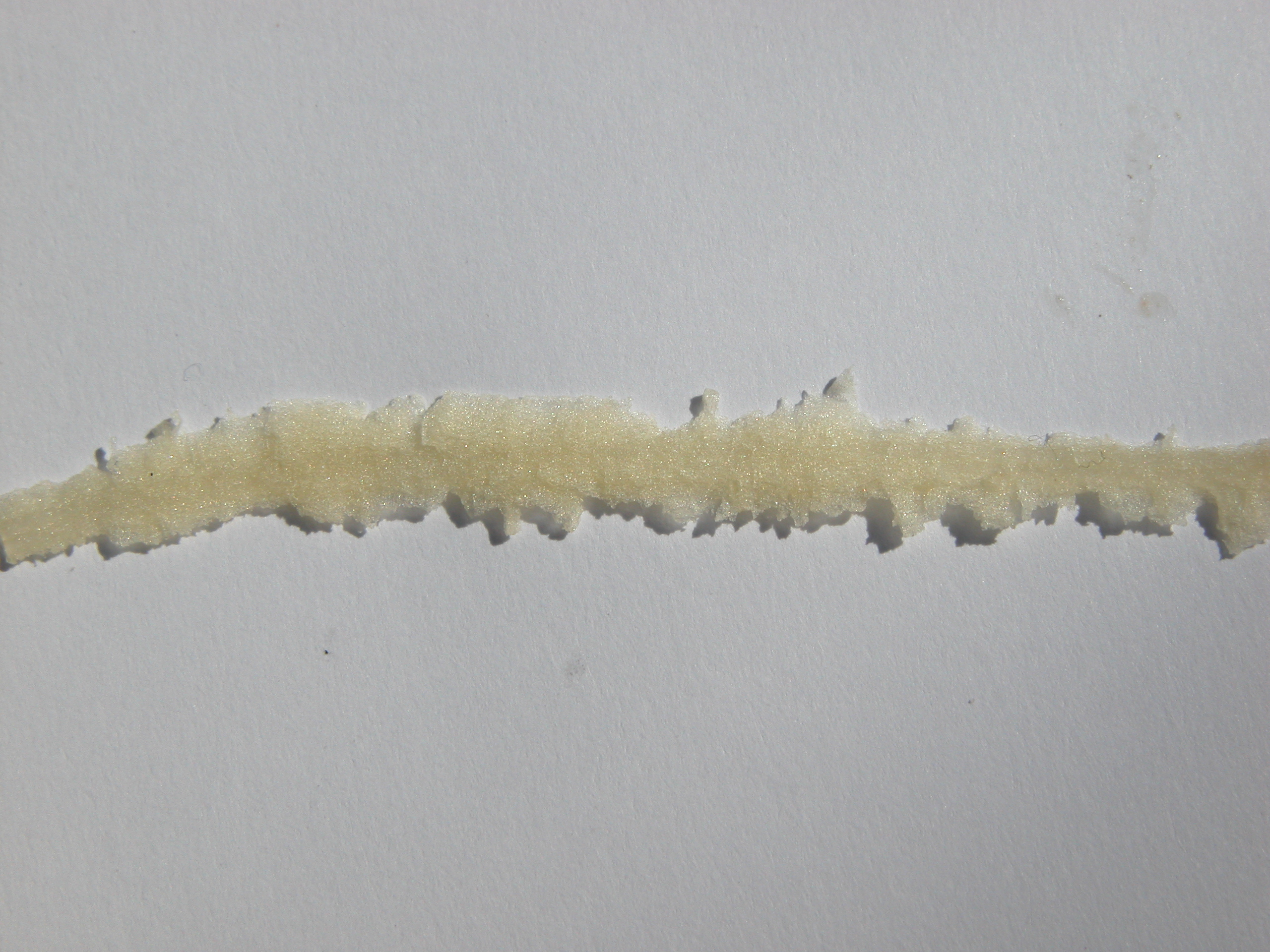

Interior wet surfaces (exposed to saved water or its vapor) are generally coated with a three-coat zinc-epoxy-epoxy system with a minimum dry movie thickness, NSF Standard 61-approved for potable water. Delve into industrial / industrial cleaning, portray, coating, and flooring subjects. Electrochemical corrosion safety of the structural parts of the tank is carried out by floor and cathodic safety items. If the steel frameworks of tank roof and higher rings of the shell show extremely high tempo of corrosion course of it is attainable to use inert-gas environment as additional technique of corrosion protection. Moreover, you should provide periodic examination of the complete surface of the tank not lower than as quickly as in each 5 years for revealing corrosion injury and the areas of surface with broken pain coating. This causes potential for the minimize materials not meeting quality requirements and being discarded. The residual materials is oftentimes extraordinarily thick, difficult to maneuver and offering a solution that did not instantly impact ongoing production was the most important problem. If the tank is no longer in use, the client shouldn't move ahead until the tank is eliminated. If the tank is found to be leaking, the property proprietor on the time of the leak discovery is accountable. In addition, consumers should make positive to have the furnace inspected (even in the summer), to ensure that there is no drawback with the tank.

This causes potential for the minimize materials not meeting quality requirements and being discarded. The residual materials is oftentimes extraordinarily thick, difficult to maneuver and offering a solution that did not instantly impact ongoing production was the most important problem. If the tank is no longer in use, the client shouldn't move ahead until the tank is eliminated. If the tank is found to be leaking, the property proprietor on the time of the leak discovery is accountable. In addition, consumers should make positive to have the furnace inspected (even in the summer), to ensure that there is no drawback with the tank.Portuguese - Balmoral Tanks corporate profile brochure

The solely true approach to know if a tank is leaking is to have it removed. Were you advised that the oil tank cleanup will price $10,000.00 to $15,000.00? If you answered yes to any of these questions, you want an expert second opinion about your leaking oil tank. 80% of the callers we get that reply sure to every question we have found do not want remediation. Texas Metal Tanks is proud to fabricate the most effective trying and highest high quality tank in your rainwater or well water storage needs.

CYLINDRICAL STEEL WATER STORAGE TANKS

You have to be assured your set up will be completed by subject material experts that can anticipate and solve issues before they happen. And you need to know that you have proven trade specialists that have the capability and suppleness to deliver value at any point in your storage tank lifecycle. In other words, the design hydrostatic pressure is the maximum strain that the tank shell course should have the flexibility to withstand when the tank is full. This stress is calculated based mostly on the load of the liquid and the peak of the liquid column. For a full tank, the design hydrostatic pressure is the best liquid strain that acts on the bottom of the tank shell course. This is calculated as the product of the liquid’s specific weight and the maximum top of the liquid, measured from the top of the tank shell.