Aquamate and World Vision in Chipapa, Zambia

All metal water tanks are designed to be built safely and rapidly on website by a small staff of skilled technicians. Since 1986, Aquamate has designed, manufactured and put in thousands of Poly Lined Steel Water Tanks in sizes from 5,000 to 200,000 Gallons. With more than 30 years of analysis and improvement, an Aquamate metallic water tank is the first choice for Durable, Reliable and Affordable massive quantity water storage. Aquamate presents an trade leading 20 Year "No Service Costs" Warranty. Our metal water tanks have three primary applications – rainwater storage, fireplace suppression water storage, and properly water storage. Aquamate has been manufacturing galvanized metal water tanks on the market since 1986.

OUR STAINLESS STEEL PANEL MANUFACTURING STEPS

You can use both a roller or spray tools, depending on the size of the tank and the tools out there to you. If you use a roller, remember to roll from aspect to side as a substitute of up and down. Spray paints are sometimes simpler to use and supply better coverage on irregular surfaces, whereas brush-on paints could additionally be more suitable for bigger, linear objects. Each pallet weighs lower than 1000kg and can be unloaded separately - eliminating the necessity for cranes or different expensive heavy tools. No special expertise or tools are needed to assemble – the bolting system requires solely an influence wrench. If a tank needs repair, solely the panels concerned must be changed - not the entire tank. Problems with plastic, concrete, and non-modular steel tanks can mean the entire tank must be changed.

Aquamate 12,000 US Gallon UR3D205 Water Tank Specification

The galvanized steel roof incorporates manufacturing facility fashioned and punched excessive rib roof panels which create a sturdy and weatherproof roof construction. Painting a metallic water tank is an effective way to guard and extend its life. It can also be an opportunity to beautify your water tank, synchronising its look with current equipment or architecture, or making use of a logo or branding. Before painting, it is essential to organize the surface by eradicating any unfastened paint and rust. This may be accomplished utilizing an electric grinder with a sanding wheel, and treating rusty areas with a rust converter. The next step is to prime the tank, utilizing an oil-based primer for one of the best results.

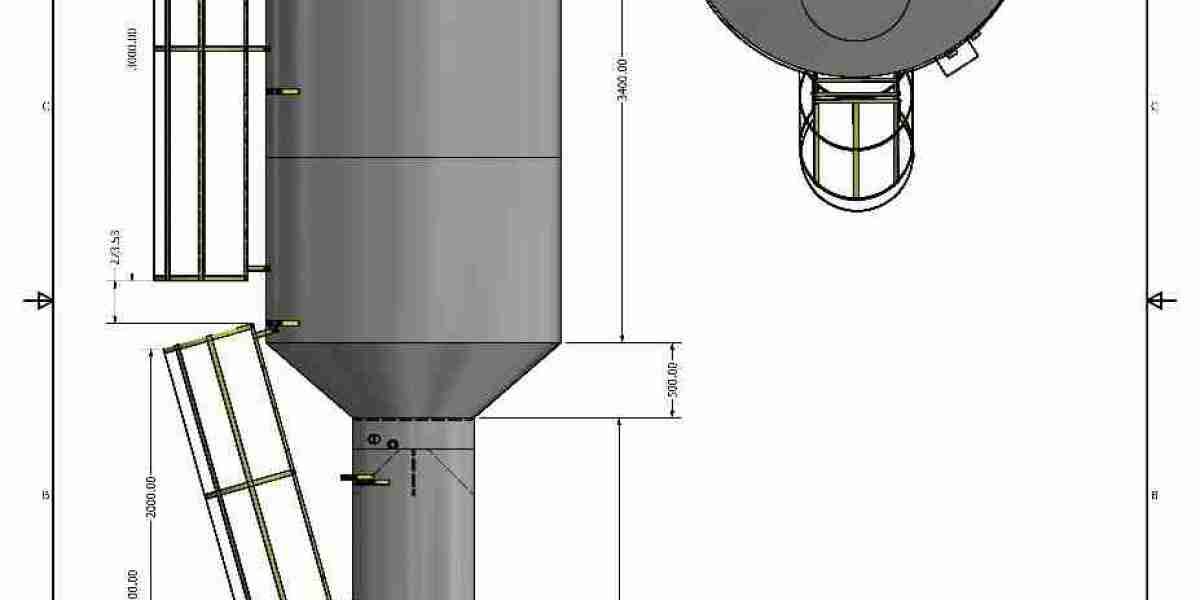

These characteristics have a tendency to show vital efficiency benefits in low stress and low irrigation rate applications. Sieve trays are merely metal plates with holes in them. Vapour passes straight upward by way of the liquid on the plate. The association, number and measurement of the holes are design parameters.

Structured packings usually consist of thin corrugated metallic plates or gauzes organized in a way that they pressure fluids to take sophisticated paths by way of the column, thereby creating a big floor space for contact between completely different phases.

Structured packings usually consist of thin corrugated metallic plates or gauzes organized in a way that they pressure fluids to take sophisticated paths by way of the column, thereby creating a big floor space for contact between completely different phases.Painting a metal water tank is an effective way to guard and prolong the life of your tank, as well as improve its aesthetics. The utility process will range depending on the scale of your tank and the equipment out there to you. Before you start priming, guarantee you have the right safety gear, similar to a respirator to protect yourself from fumes. Read and follow the producer's instructions for the primer you've chosen.

Standards and quality certifications

To ensure the paint job is long-lasting, you will want to observe correct procedures and use the proper merchandise. One essential step within the process is sealing the paint with a UV-resistant topcoat. They offer reliability, sturdiness and suppleness, making them ideal for numerous wants. With steel water tanks, you'll benefit a tailored and long-lasting answer whereas contributing to sustainable water administration. Finally, as soon as the primer is dry and the surface is easy and ready, you probably can proceed to the portray stage, following the producer's directions for the paint you've chosen.

STAINLESS STEEL PANEL WATER TANKS GRADE 304/444/316

The closed and impermeable design minimizes water loss via evaporation, while also permitting for exact management over water ranges. This closed system additionally makes it easy to take care of water high quality via filtration or therapy methods. As metallic is a singular surface, it is necessary to make use of a primer designed particularly for metallic surfaces or a multipurpose primer that's appropriate for metal. An oil-based primer will help create an even and clean end on your topcoat. It is not any wonder yow will discover our steel water tank in additional than 50 countries these days. Everywhere people profit from Buwatec Water Technology’s in style tank. Not in the least as a outcome of we offer competitive prices on a regular basis.